Anchoring is required, only when fitting with a rubber sealing ring are used or, at the points where valves are installed. Anchoring is not necessary, when heat-welded fittings are used.

HDPE pipes can, at ambient temperature, can be bent to a radius of R=12-20 times above their outside diameter (DIN 16933 specification ).

| Size (mm) |

SDR 26 (mtr.) |

SDR 21 (mtr.) |

SDR 17 (mtr.) |

SDR 13.6 (mtr.) |

SDR 11 (mtr.) |

SDR 9 (mtr.) |

|---|---|---|---|---|---|---|

| 20 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.7 |

| 25 | 0.5 | 0.6 | 0.7 | 0.7 | 0.7 | 0.8 |

| 32 | 0.6 | 0.7 | 0.8 | 0.8 | 0.9 | 0.9 |

| 40 | 0.7 | 0.9 | 0.9 | 1.0 | 1.0 | 1.1 |

| 50 | 0.9 | 1.0 | 1.0 | 1.1 | 1.2 | 1.2 |

| 63 | 1.0 | 1.2 | 1.2 | 1.3 | 1.4 | 1.4 |

| 75 | 1.1 | 1.3 | 1.4 | 1.5 | 1.5 | 1.6 |

| 90 | 1.3 | 1.5 | 1.6 | 1.7 | 1.7 | 1.8 |

| 110 | 1.5 | 1.7 | 1.8 | 1.9 | 2.0 | 2.1 |

| 125 | 1.6 | 1.8 | 2.0 | 2.1 | 2.2 | 2.3 |

| 140 | 1.7 | 2.0 | 2.1 | 2.2 | 2.4 | 2.5 |

| 160 | 1.9 | 2.2 | 2.3 | 2.5 | 2.6 | 2.7 |

| 200 | 2.2 | 2.5 | 2.7 | 2.9 | 3.0 | 3.2 |

| 225 | 2.4 | 2.7 | 2.9 | 3.1 | 3.3 | 3.4 |

| 250 | 2.6 | 3.0 | 3.1 | 3.3 | 3.5 | 3.7 |

| 280 | 2.8 | 3.2 | 3.4 | 3.6 | 3.8 | 4.0 |

| 315 | 3.0 | 3.4 | 3.7 | 3.9 | 4.1 | 4.3 |

| 355 | 3.3 | 3.7 | 4.0 | 4.2 | 4.4 | 4.7 |

| 400 | 3.5 | 4.0 | 4.3 | 4.5 | 4.8 | 5.0 |

| 450 | 3.8 | 4.4 | 4.7 | 4.9 | 5.2 | 5.5 |

| 500 | 4.1 | 4.7 | 5.0 | 5.3 | 5.6 | 5.9 |

| 560 | 4.4 | 5.1 | 5.4 | 5.7 | 6.0 | 6.0 |

| 630 | 4.8 | 5.5 | 5.8 | 6.2 | 6.5 | 6.8 |

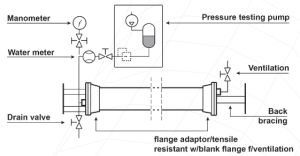

When a Polyethylene pipeline is sealed under a pressure test there will be a reduction in pressure ( pressure decay ), even in a leak free system, due to the visco elastic ( creep ) response of the material. This pressure decay is non-linear in an unconstrained pipe.